Leakage at various points in pipelines found in chemical plants creates emissions. All such leakage points can be detected using various methods and instruments and should be noted by the plant engineer. Critical leakage points include flanged gasket joints and the Valve / pump gland packing, etc. Today the chemical process industry is gearing itself towards safer technology for better environmental protection and it has become every process engineer’s responsibility to design plants that limit damage to the environment through the prevention of leakage of any toxic chemicals.

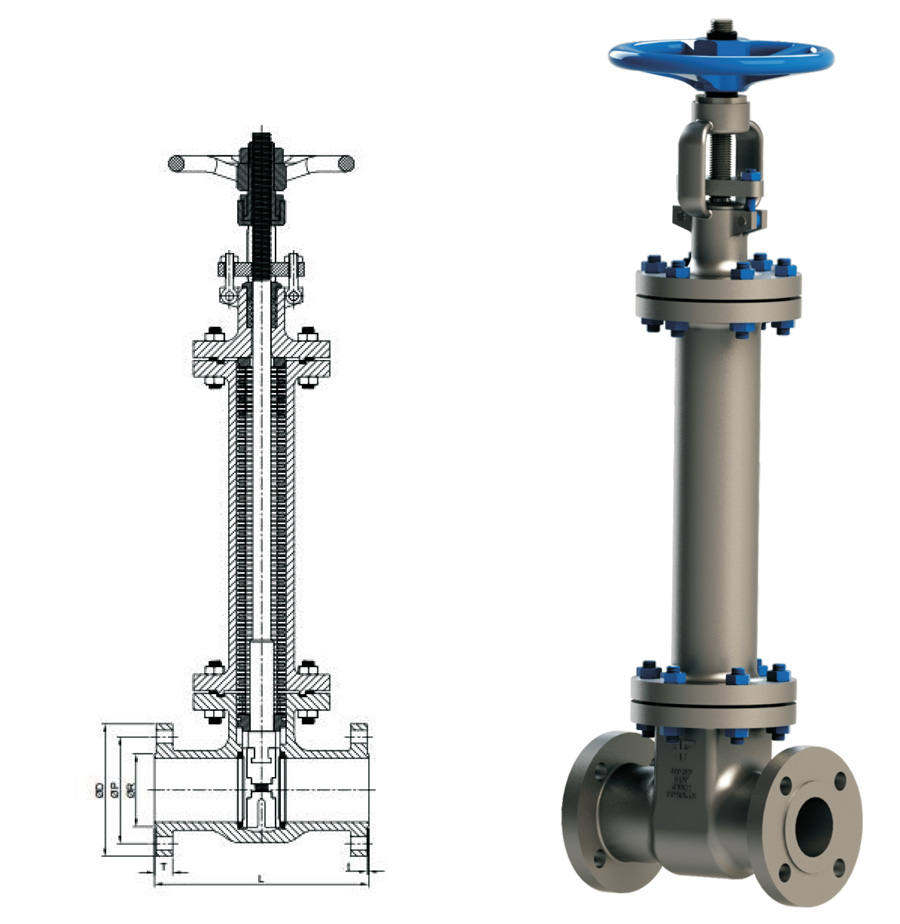

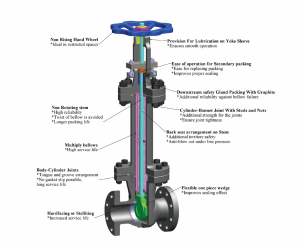

BELLOW CONSTRUCTION

The bellow cartridge is welded to both the Valve Bonnet and the Valve stem. The bellow cartridge has a number of convolutions and these convolutions become compressed or expanded depending upon the movement of Valve stem. (Scientifically speaking the bellow gets compressed when the Valve is in the open position and expanded when the Valve is in the closed condition). It is important to properly install the Valve bodies. The bellow can be sealed to the Valves in two different ways. Firstly, the bellow can be welded to the Valve stem at the top and the Valve body on the bottom. In this case the process fluid is contained inside the bellow or in second method the bellow is welded to the Valve stem at the bottom and the body on the top. In this case the process fluid is contained in the annular region between the Valve Bonnet and bellow (from the outside).

The bellow is a critical component and forms the heart of the bellow seal Valves. To avoid any twisting of the bellow the Valve must have a stem with linear movement only. This can be achieved using a so-called sleeve-nut at the Yoke portion of the Valve Bonnet. A handwheel is fitted onto the sleeve-nut which effectively transfers a rotary motion of the handwheel into a linear motion in the Valve stem.